1. Initial Design Phase. Our technical team conducts preliminary analysis of the customer's product mold, analyzes the feasibility of the product mold, and checks the product drawings in detail. This mainly includes key product dimensions, product structure, and draft angles, which are very helpful for the later stages of the mold.

2. Technical points that technicians need to confirm in the drawings provided by the customer:

1. Product material; 2. Product shrinkage rate;

3. Product dimensional accuracy; 4. Product surface requirements;

5. Number of mold cavities;

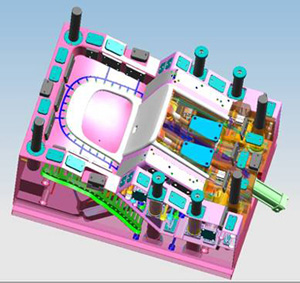

6. Mold usage requirements, etc. After determining these key technical points, we start the 3D design and development of the mold for the customer's product.

3. How to convert physical products into data? If there is existing physical 3D point data, we have three ways: 1. Data machine drawings and 3D data product models; 2. If you have product samples, we can perform surveying, mapping, photography, and laser scanning; 3. If you have product photos, we can scan and convert them directly into 3D data proportionally. After obtaining this data, technicians mainly use 3D software UG to process the data. First, convert existing point data into line data, then from line data to surface data, and finally from surface to physical model.

4. After the product model design is completed, the technical designers need to design the mold outlet. Using 3D software UG for product mold design, the design needs to be combined with our company's existing processing technology. After the mold structure design is completed, it is handed over to the minister for review. After approval, the processing of each component and later assembly can be carried out according to the data processing flow. This is the entire mold production process.